Discover the remarkable journey of mold remediation for a flight simulator transported from Canada to Singapore. This case study delves into the challenges and innovative solutions provided by DRS, showcasing our expertise in handling complex mold issues in harsh environments.

Tackling Mold in a High-Tech Flight Simulator

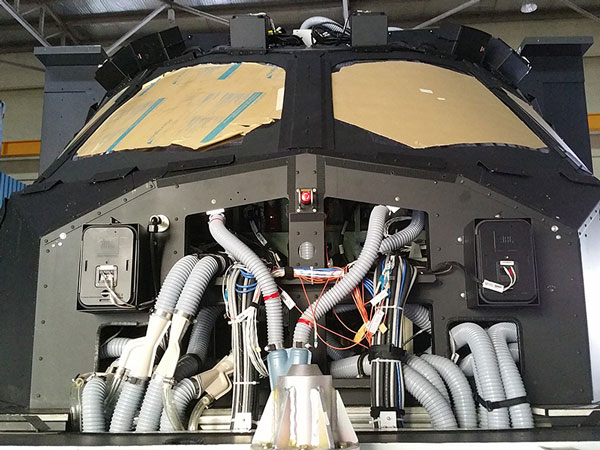

A high-tech flight simulator, relocating from Canada’s temperate climate to Singapore’s tropical conditions, encountered a severe mold infestation. The humid Singaporean weather catalyzed fungal growth, rendering the simulator hazardous for use. This presented a unique challenge, requiring urgent and effective mold removal solutions to avoid substantial financial loss and operational disruptions.

Comprehensive Mold Decontamination: Inside-Out Restoration

DRS, a leader in mold remediation, was tasked with restoring the simulator to its pristine condition. Our approach involved:

- Advanced Drying Techniques: Employing state-of-the-art drying equipment, we meticulously eliminated excess moisture from the simulator’s intricate crevices.

- Comprehensive Mold Decontamination: We executed thorough decontamination of all mold-impacted areas, both internally and externally, ensuring a complete mold removal.

- Indoor Air Quality Assurance: Post-remediation, we conducted scientific Indoor Air Quality (IAQ) tests, analysis, and reporting to validate the effectiveness of our solutions.

Minimizing Downtime: Swift Return to Operational Efficiency

The strategic intervention by DRS led to substantial benefits:

- Cost-Effective Solution: Our client avoided the hefty expense of purchasing a new simulator.

- Business Continuity: The simulator was swiftly restored with minimal operational downtime.

- Health and Safety: Ensuring a mold-free, safe environment for simulator users.

- Quality Assurance: IAQ testing confirmed a successful remediation, boosting client confidence.

Demonstrating DRS’s Mold Remediation Mastery

This case study exemplifies DRS’s proficiency in tackling complex mold issues in challenging environments. Our comprehensive mold remediation services not only saved significant costs but also reinstated operational efficiency and safety standards.